Gear units that are properly designed and carefully maintained fulfil their function properly over many years. Overload, extreme conditions and other influences, however, result in wear or defects in every gear unit – regardless of the manufacturer. This is why Kissling has provided well-developed services services and maintained a vastspare parts warehousesince the company was founded.

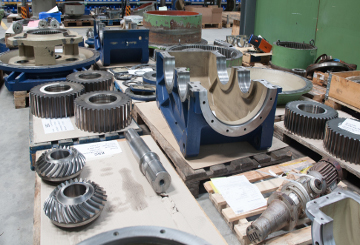

The Kissling Service Centre provides the entire range of services for gear units. These services are not just for our own products, but also for third-party products. Well-trained experts with many years of experience provide the kind of fast, efficient and professional service that is only possible with expertise acquired over ninety years of gearbox manufacturing.

A good example for our quality, reliablity, robustness and sustainiability is the sluice in Kembs.

The gear units installed at the Kembs sluice in France, P-1419s - ZKE-154, from the 1990s are now being overhauled one by one. We, Kissling AG, would like to note that the gear units have had no failures over the period from 1992 up to and including today.

Therefore, EdF Kembs trusts Kissling AG once again and orders a new sluice gear unit and the revision for the three gear units which are in operation. By ordering the new sluice gear, vessel traffic on the Rhine is guaranteed. Thus, the first gear unit could be removed for the overhaul without major interruption of operation and the new unit could be reinstalled directly.

We have had an in-house sandblasting system since the summer of 2017. We use it to remove the old paint from the gearboxes that are sent to us for inspection.

We also offer our in-house sandblasting as a service. Sandblasting is suitable for parts with volumes up to 2m3, dimensions of maximum 220 x 350 x 300 cm and a maximum weight of 6 tonnes.

Please contact our sales team for more information.